Automated Economic Dispatch for CCHP Systems or Central Plants

Partners: Pacific Northwest National Laboratory, U.S. Department of Energy (DOE), Frontier Energy, Burrstone Energy Cooperation, and National Grid

Location: Utica, NY

Connected Community type: Approximately 10 existing mixed commercial buildings, including college, hospital and nursing home campuses.

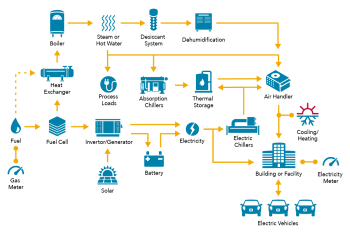

Distributed energy resources (DERs) installed: Existing equipment in the form of a CCHP system. The CCHP includes four gas generators, exhaust energy heat recovery steam generators and engine hot water recovery.

Automated dispatch: The primary focus of this project is to optimize generation dispatch using day-ahead export and import prices of electricity and natural gas prices. A second focus includes performance monitoring, automated fault detection and diagnostics, and the use of automated continuous commissioning algorithms for selected CCHP components.

Controls: The project utilizes the VOLTTRON™ hosted automated economic dispatch software to automatically dispatch local generation.

Value proposition: From the CCHP building operator perspective, this project was focused on helping reduce utility bill and fuel costs when the site is exposed to dynamic utility import and export prices. From the utility perspective, they get better visibility of their imports and exports from customers 24 hours ahead of time.

Grid issues addressed: The project is focused on improving the imbalance between generation and demand and alleviating any unnecessary constraints on the grid.

Grid services used: The primary focus has been to minimize the energy cost of a CCHP system.

Experience/highlight: The VOLTTRON™-based automated economic dispatch system deployment and testing were initiated in late fall 2018 in Utica, New York, at Burrstone Energy Corporation’s CCHP plant, which contains four natural-gas-fueled generators serving a college, hospital, and nursing home. Once operational, the system established and evaluated operational strategies, sending commands to the CCHPs regarding whether the generators should run and in which modes they should operate.

The testing, which began in spring 2019, produced several key outcomes:

- The automated system successfully dispatched control signals to the CCHP.

- A benchmarking analysis, which examined a few days of operation in March and compared the economic dispatch system to the previous CCHP control method, demonstrated savings on the order of $50 per day. This equates to $20,000 per year in additional profit from a CCHP.

- Preliminary results strongly suggest the system can be deployed in the field and customized at lower cost than existing options.